Ideen sind unsere Stärke

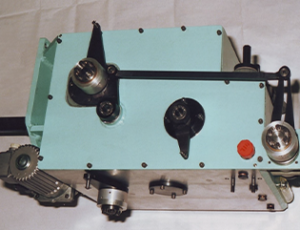

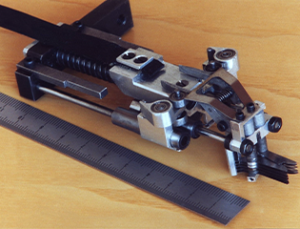

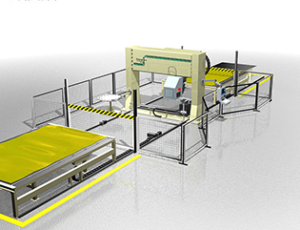

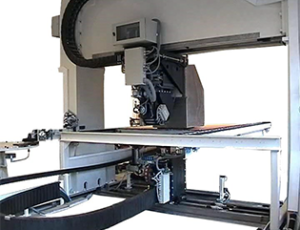

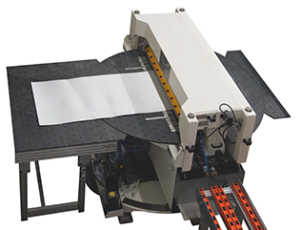

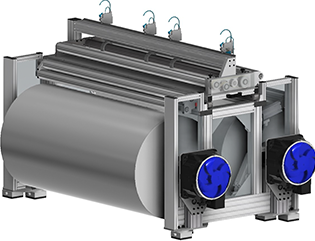

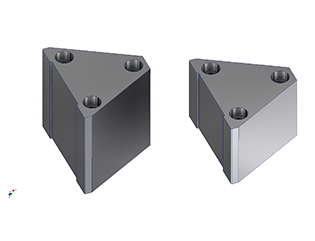

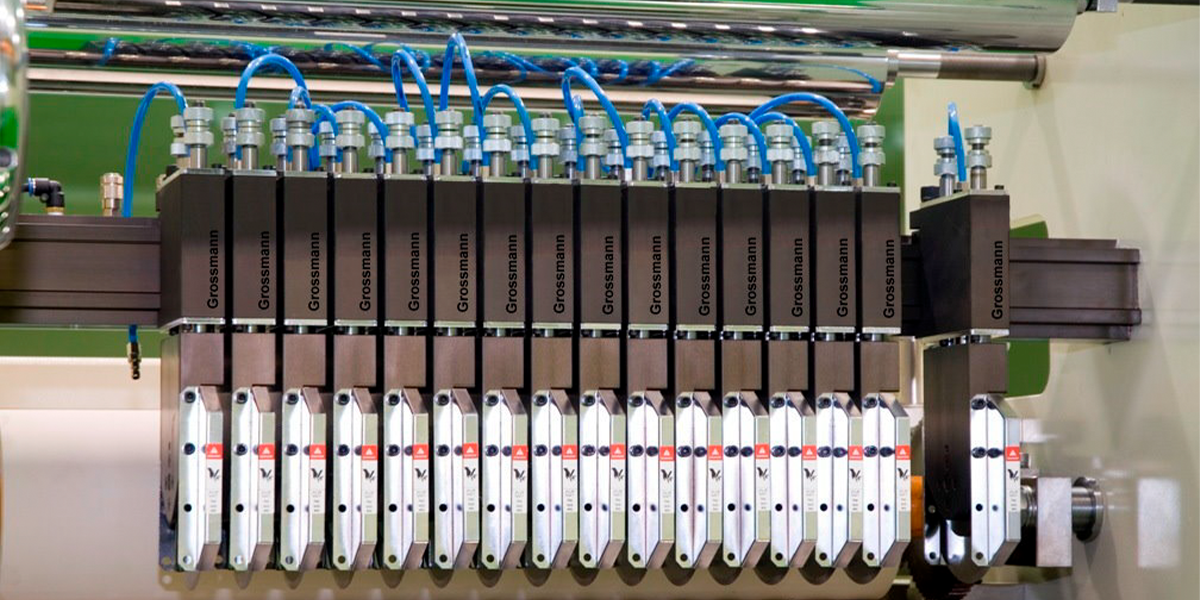

Schwenkschere mit zwei austauschbaren Konturschnitt-Messerkassetten

Erfahren Sie mehr über diesen Produktbereich

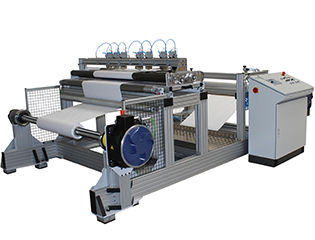

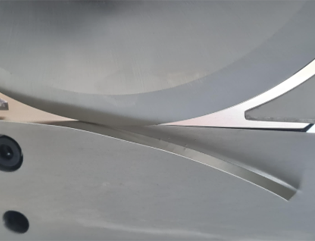

Schneidsysteme

Erfahren Sie mehr über diesen Produktbereich

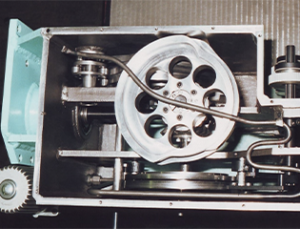

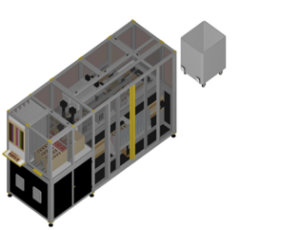

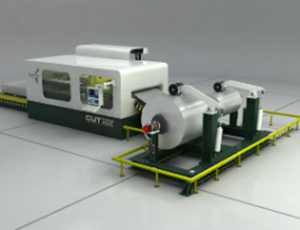

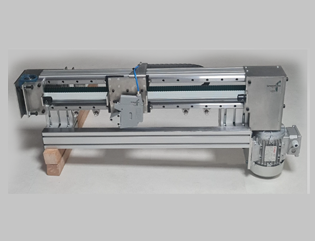

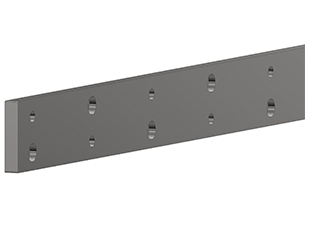

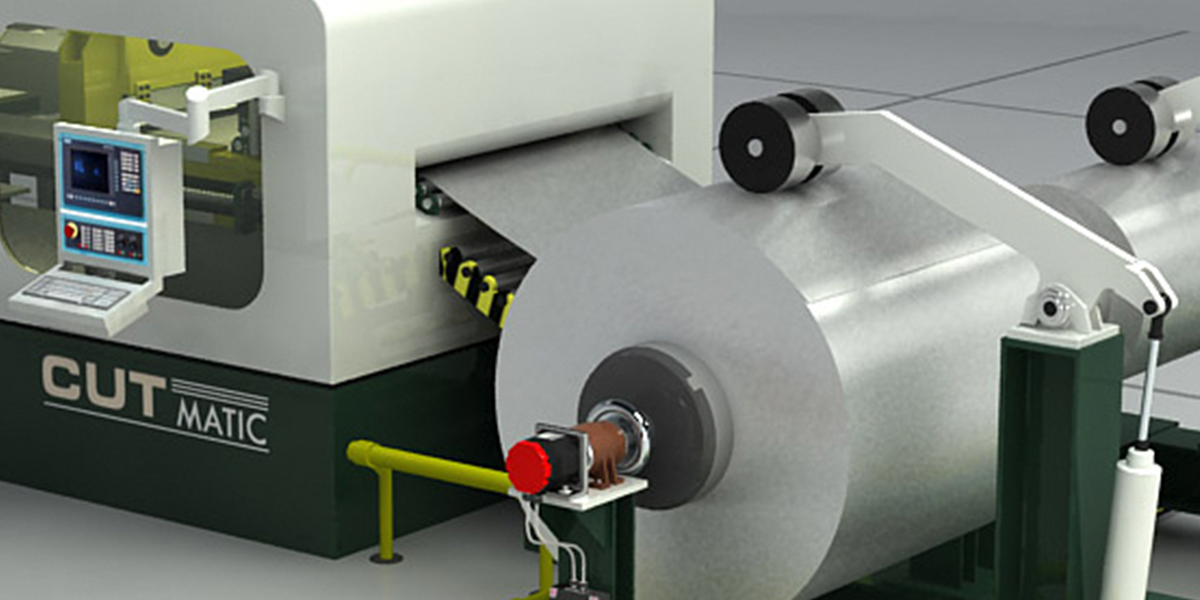

Platinenschneidanlage Cutmatic

Erfahren Sie mehr über diesen Produktbereich

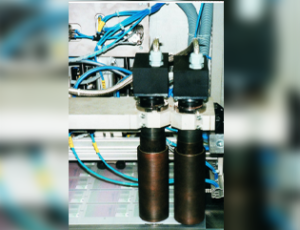

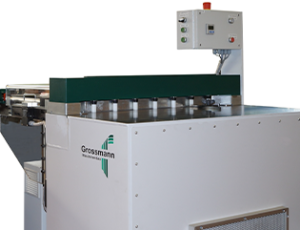

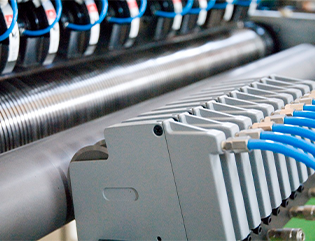

Baugruppen und Maschinen zur Bahnbearbeitung

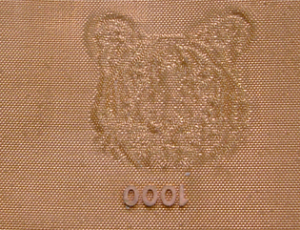

Erfahren Sie mehr über diesen ProduktbereichMetal Honeycomb and Corrugated Core Sandwich Panels

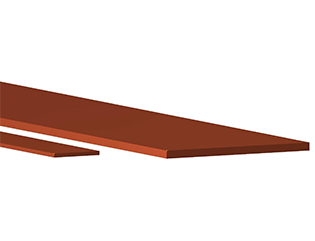

Aluminum sheet, 0.3 mm to max. 2 mm thick, is the basis of these sandwich panels. Aluminum honeycomb sandwich panels are generally welded, corrugated core panels are bonded.

The area weight is low. A 20 mm thick aluminum honeycomb sandwich panel has an area weight of approx. 8 kg/m² to 10 kg/m². The area weight of aluminum corrugated core panels with the same thickness is approx. 5 kg/m² to 8 kg/m².

Metal honeycomb and corrugated core sandwich panels are very durable, vibration-damping, resistant to corrosion and fire. They are 100% recyclable.

The possible applications are very diverse:

Subways and Trains: Shelves and storage surfaces in delivery vans, doors, and wagon linings.

Ships: Interior lining and partition walls.

Elevator Cabs: Walls, floor, ceiling, doors, and exterior decor panels.

Machinery: Vibration-damping machine enclosures, feed and discharge hoppers and surfaces for oils, paints, coolants, etc., display mounting panels, work surfaces.

Armored vehicles and military sector: Bullet and splinter protection.

Construction: Curtain facades, ceilings, roofs, partition walls, raised floors.

Sandwich panels for exterior facades:

15 mm thick aluminum honeycomb sandwich panels with epoxy fluorocarbon coating are suitable for exterior facades, for example. They are very durable, resistant to wind pressure, corrosion, fire, and 100% recyclable.

The area weight is 9 kg/m². Transport, processing, and installation are simple. Standard elements for mounting on facades are available.

Grossmann B.V.

Markt 19

NL6071 JD Swalmen

Info@grossmann.de