Ideen sind unsere Stärke

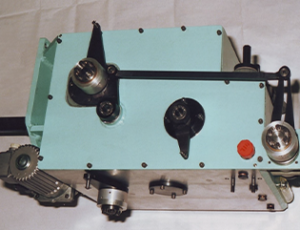

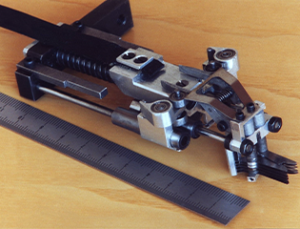

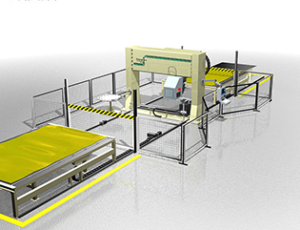

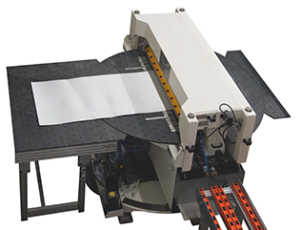

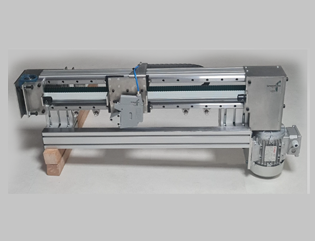

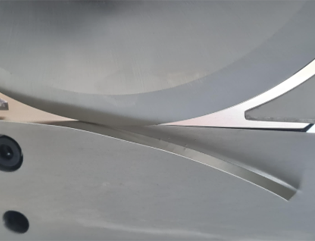

Schwenkschere mit zwei austauschbaren Konturschnitt-Messerkassetten

Erfahren Sie mehr über diesen Produktbereich

Schneidsysteme

Erfahren Sie mehr über diesen Produktbereich

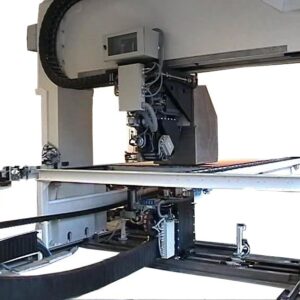

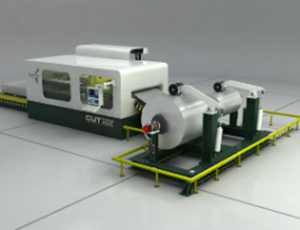

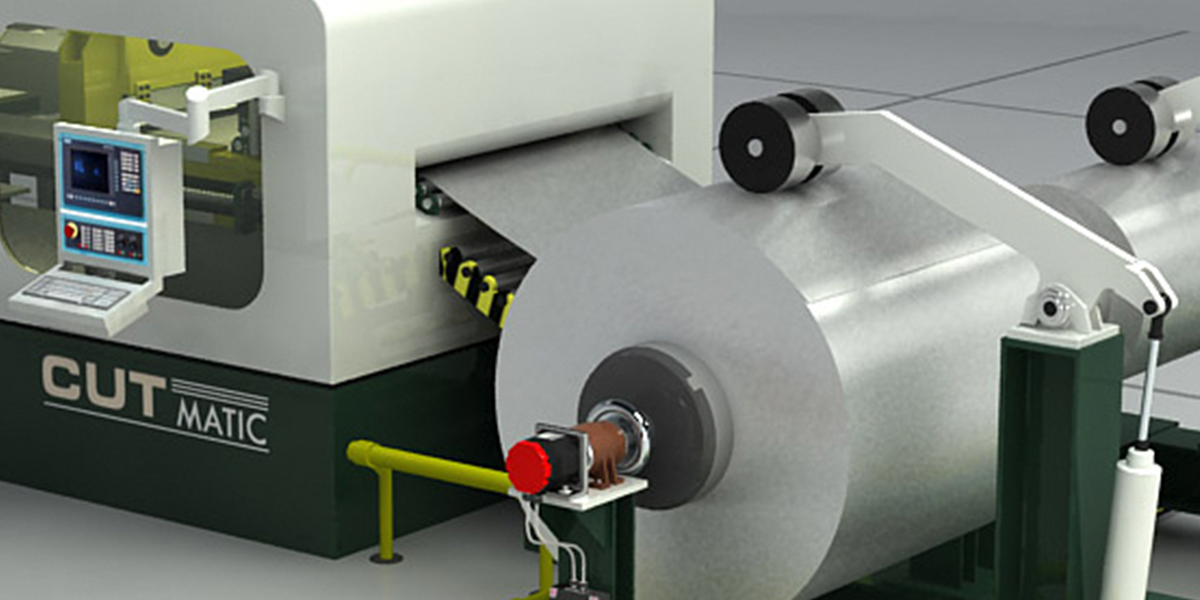

Platinenschneidanlage Cutmatic

Erfahren Sie mehr über diesen Produktbereich

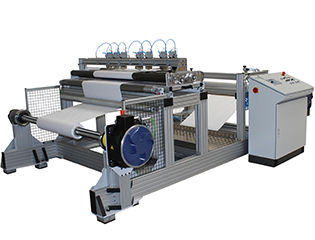

Baugruppen und Maschinen zur Bahnbearbeitung

Erfahren Sie mehr über diesen ProduktbereichWatermark Production for Banknotes

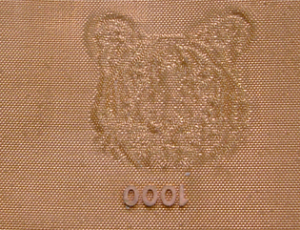

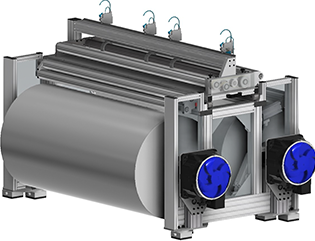

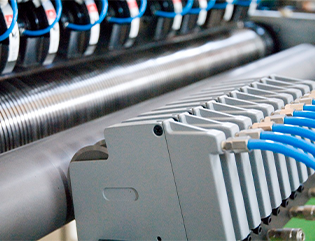

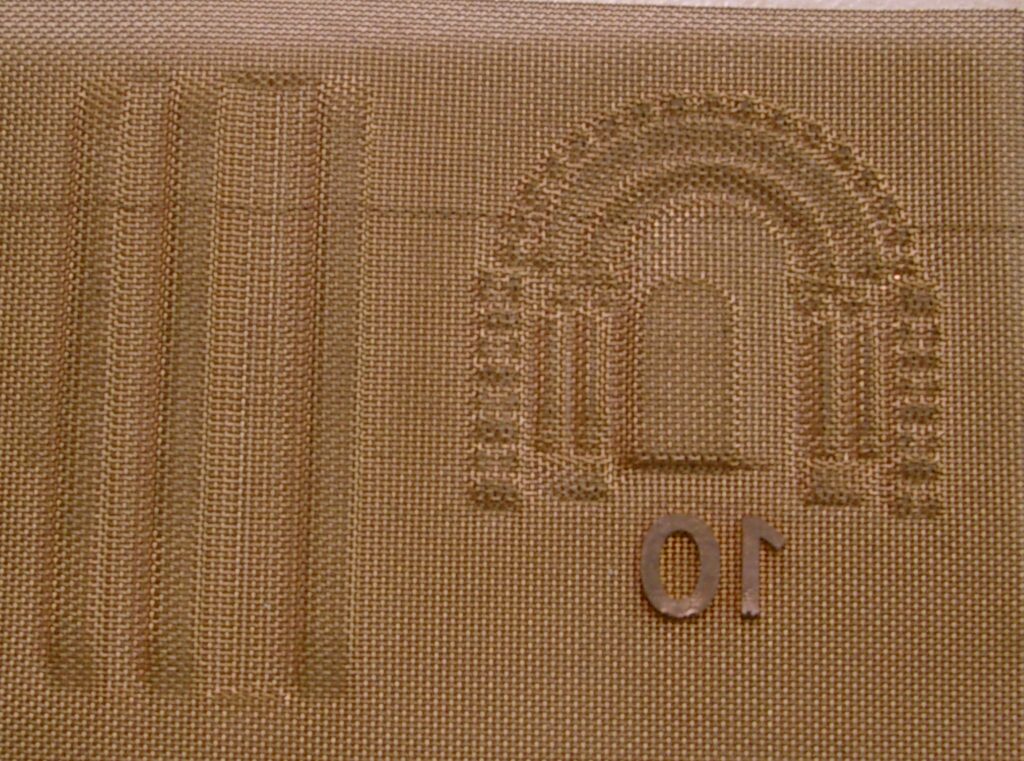

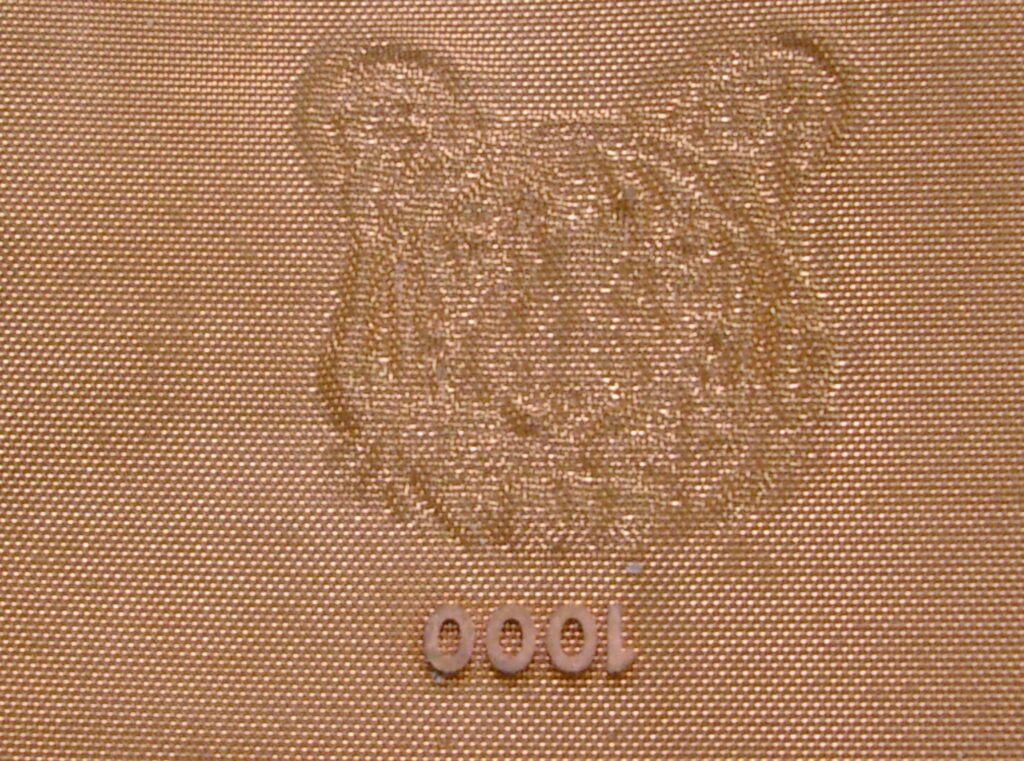

Papers with watermarks are created on a metal sieve, into which contours are embossed and metal platelets are welded.

The liquid paper pulp is applied to the metal sieve and dewatered through the sieve. In areas with elevations on the sieve, the paper becomes thinner. These areas are visible as watermarks in the finished paper.

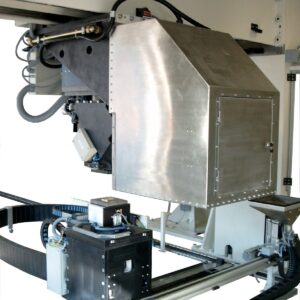

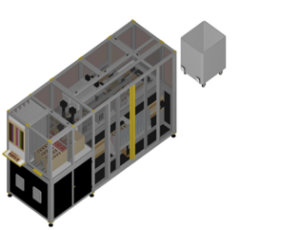

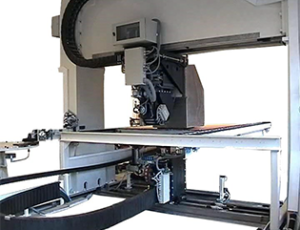

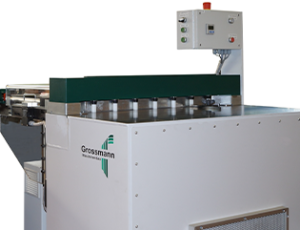

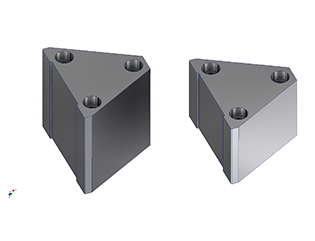

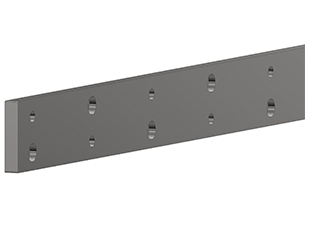

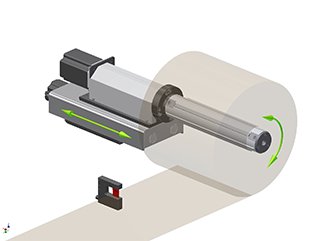

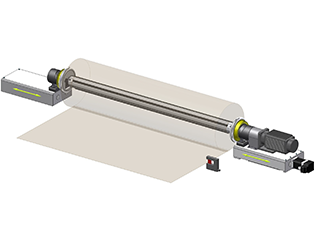

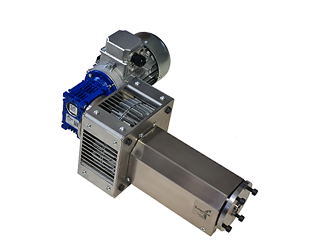

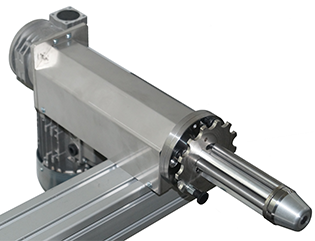

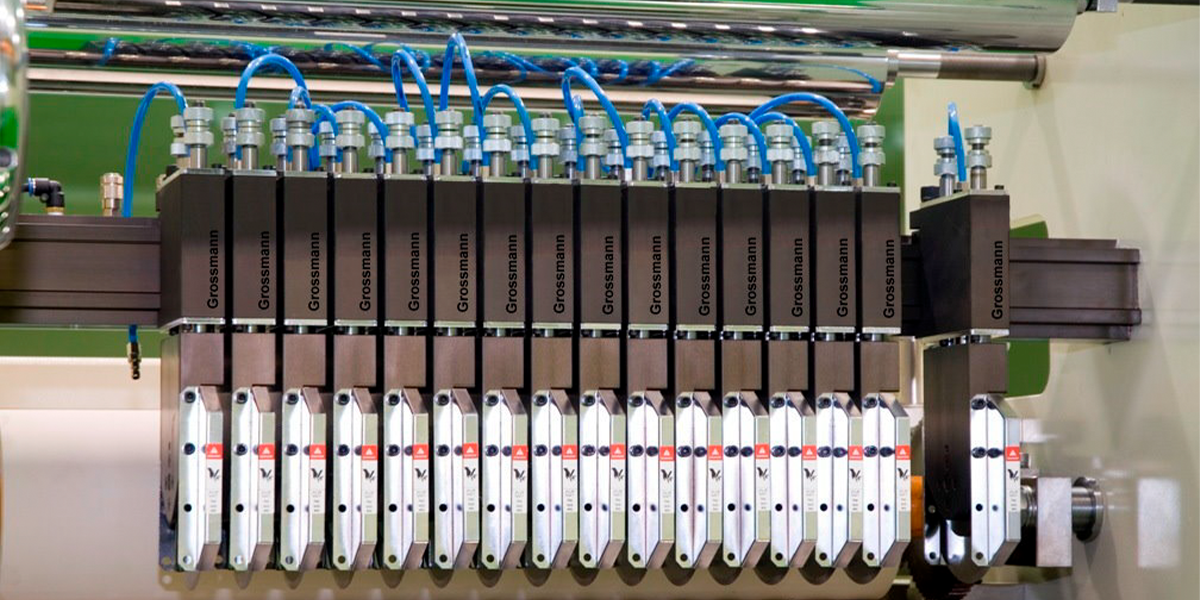

The automatic system for watermark production clamps the metal sieve independently. All embossing and tool change processes, including annealing and laser cutting, are fully automatic.

The tolerance for the embossing force is max. 1‰ of the programmed embossing force.

Grossmann B.V.

Markt 19

NL6071 JD Swalmen

Info@grossmann.de