Ideen sind unsere Stärke

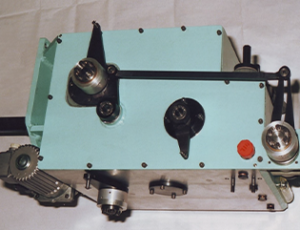

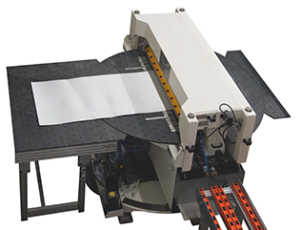

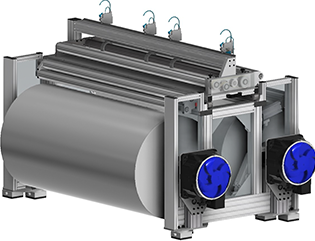

Schwenkschere mit zwei austauschbaren Konturschnitt-Messerkassetten

Erfahren Sie mehr über diesen Produktbereich

Schneidsysteme

Erfahren Sie mehr über diesen Produktbereich

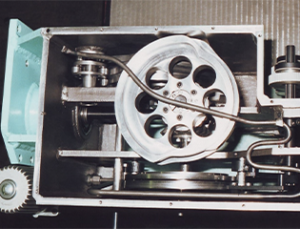

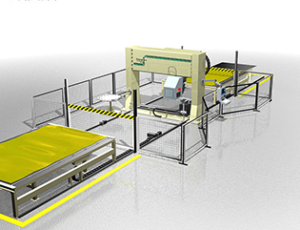

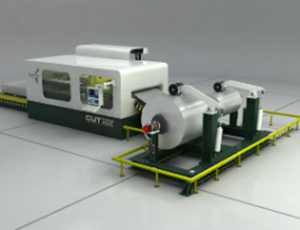

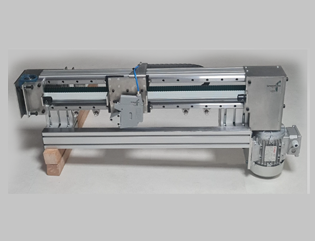

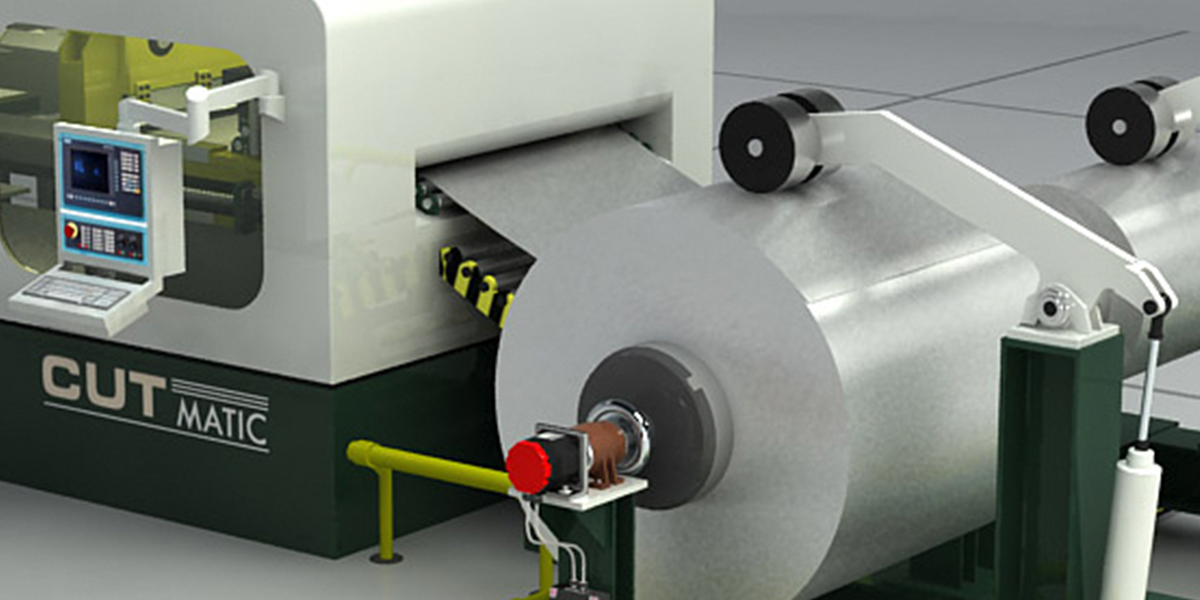

Platinenschneidanlage Cutmatic

Erfahren Sie mehr über diesen Produktbereich

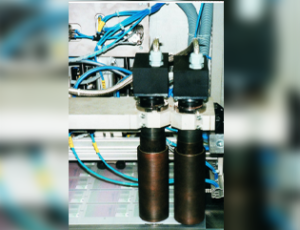

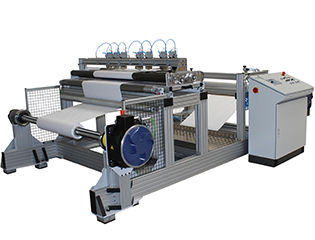

Baugruppen und Maschinen zur Bahnbearbeitung

Erfahren Sie mehr über diesen ProduktbereichTool Press for Hologram Production

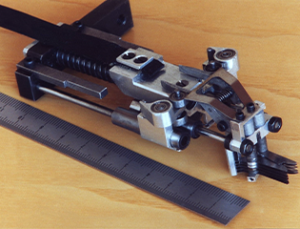

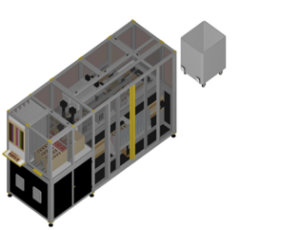

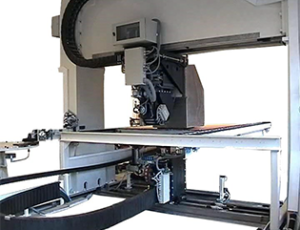

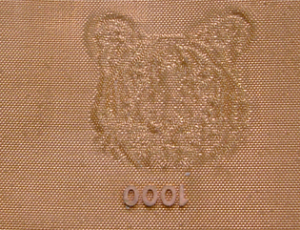

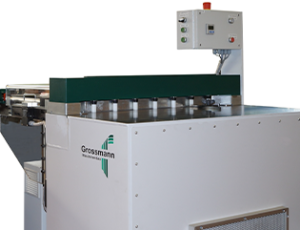

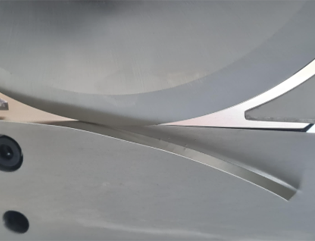

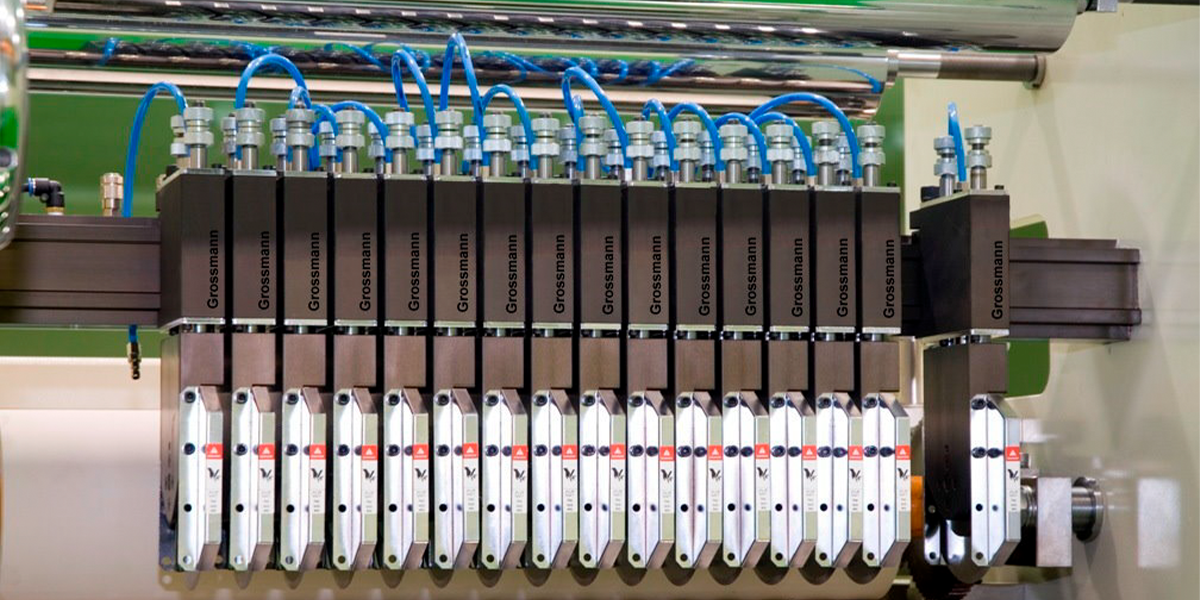

The first manufacturing step in hologram production is the embossing of a plastic plate. Several hundred embossings are applied to the plastic plate. Using a galvanic process, the actual hard metal embossing tool is produced from this. This tool is used to roll aluminum foil, creating the hologram.

Requirements for the plastic plate embossing press:

- The embossing depth is 0.6 µm.

- The material-related unevenness of the plastic plate to be embossed is greater than the embossing depth. Therefore, before each embossing, the surface flatness must be measured and the surface aligned parallel to the embossing stamp. The tolerance is significantly less than the embossing depth.

- The embossing force is servo-controlled with an accuracy of 0.1 ‰ of the maximum force.

- The embossing press operates under clean room conditions.

Grossmann B.V.

Markt 19

NL6071 JD Swalmen

Info@grossmann.de