Ideen sind unsere Stärke

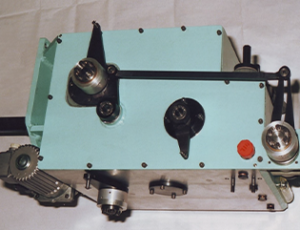

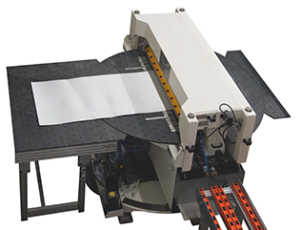

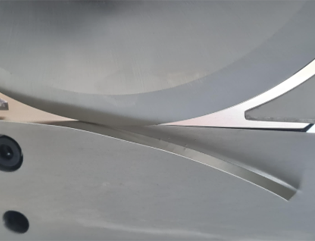

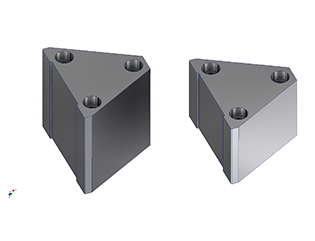

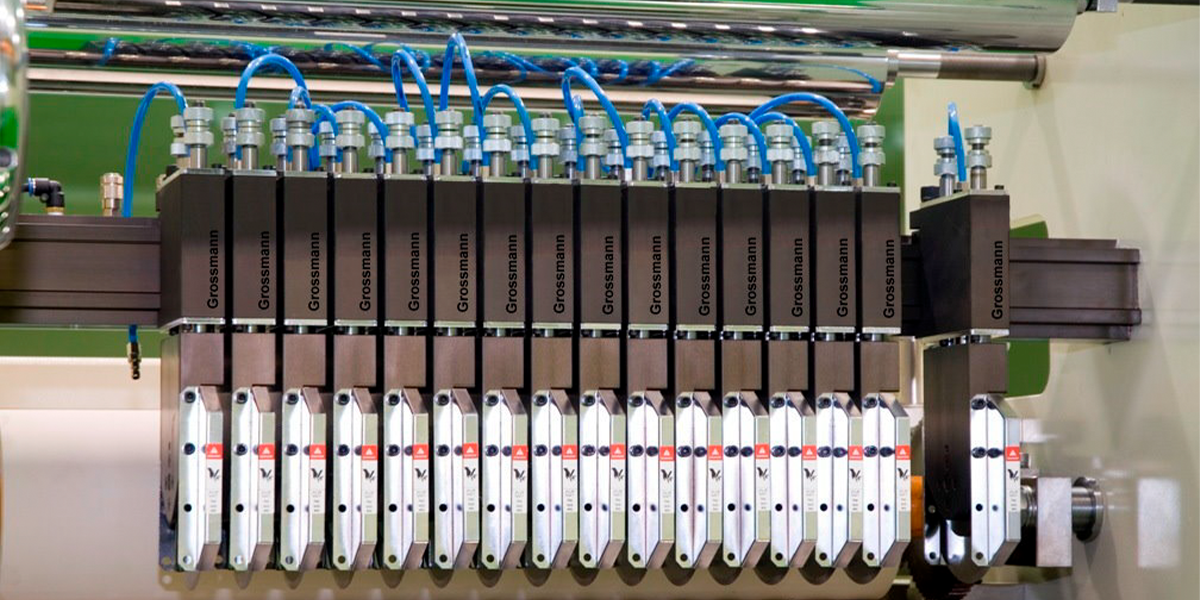

Schwenkschere mit zwei austauschbaren Konturschnitt-Messerkassetten

Erfahren Sie mehr über diesen Produktbereich

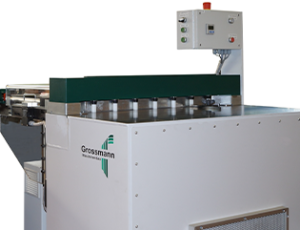

Schneidsysteme

Erfahren Sie mehr über diesen Produktbereich

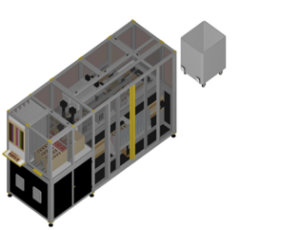

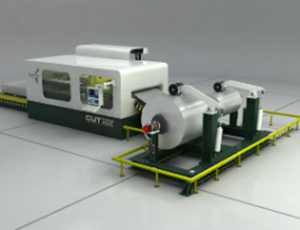

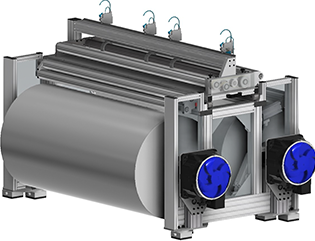

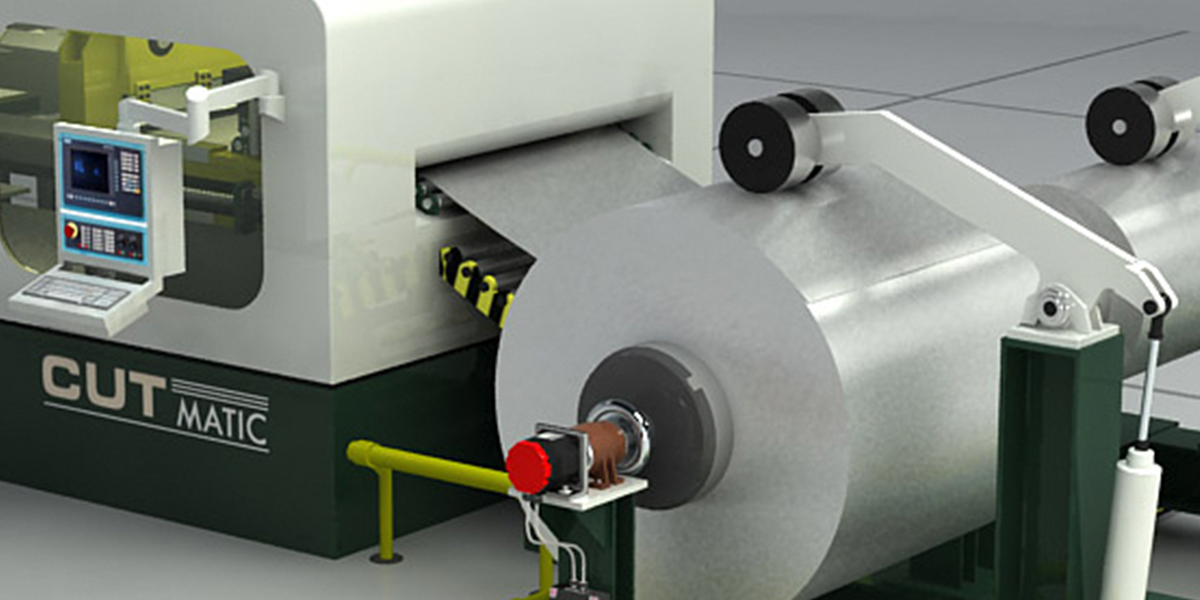

Platinenschneidanlage Cutmatic

Erfahren Sie mehr über diesen Produktbereich

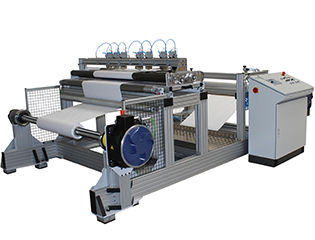

Baugruppen und Maschinen zur Bahnbearbeitung

Erfahren Sie mehr über diesen ProduktbereichCross-cutting system CUTmatic

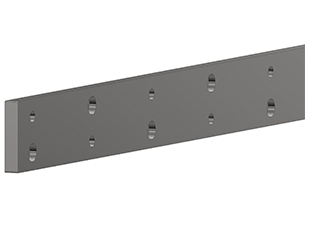

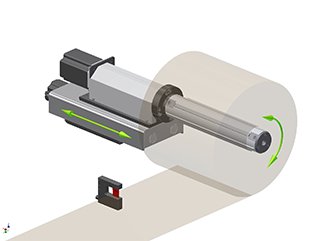

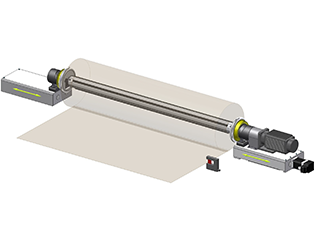

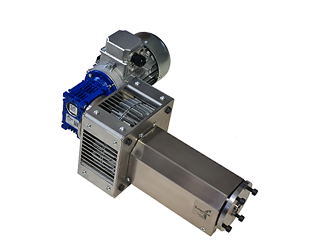

The standardized CUTmatic is configurable in our online store. The CUTmatic is built essentially from standard modules:

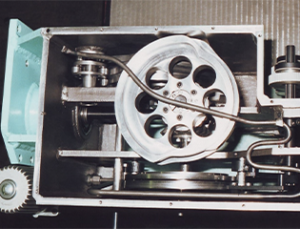

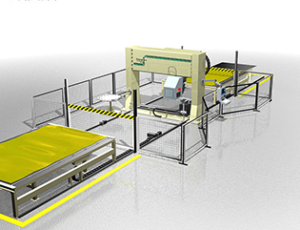

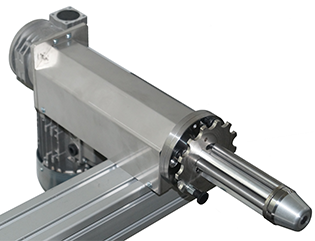

The dual coil car is built from our series elements of Winding Technology, which are also used for paper and film processing: Driven safety swing-out bearings and expanding mandrel winding shafts enable fast coil changeover. The coil inner diameter is variable. Coil weights up to 6,700 kg are possible.

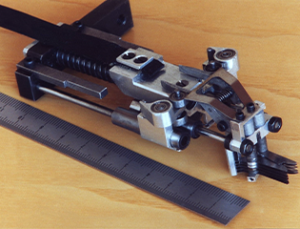

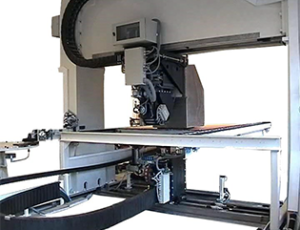

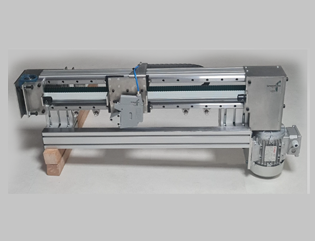

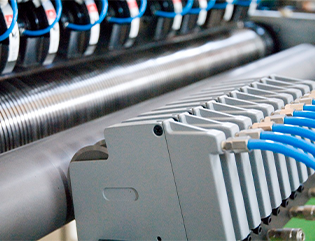

The strip is fed to the traveling, shear-shock-free shear at constant speed. This shear accelerates to strip speed, cuts with positional accuracy, and then returns to the start position for the next cut.

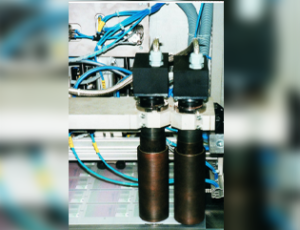

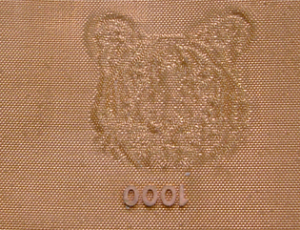

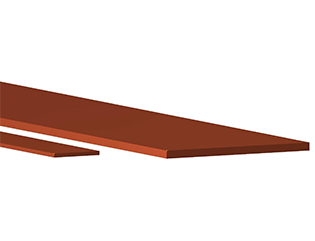

After the cut, the sheet falls vertically onto two brush plates. After laying down, the brush plates move apart very quickly, the sheet falls between vertical guides onto the sheet stack. An air cushion created in the process ensures sheet placement without surface damage.

An intermediate buffer enables continuous production during the exchange of the full sheet stack for an empty pallet.

Grossmann B.V.

Markt 19

NL6071 JD Swalmen

Info@grossmann.de