Ideen sind unsere Stärke

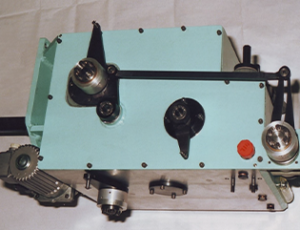

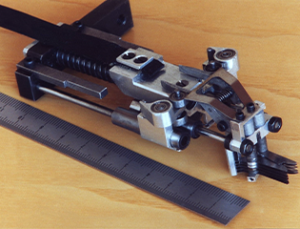

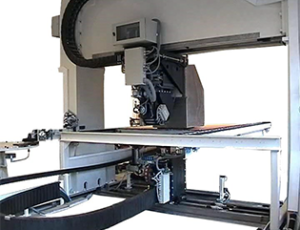

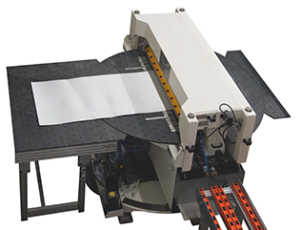

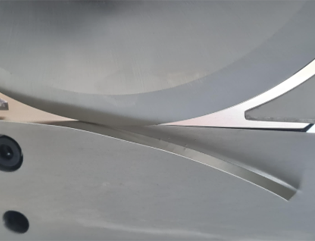

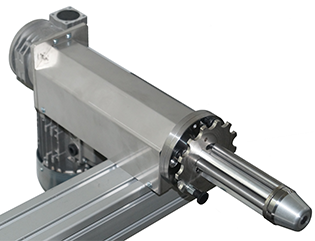

Schwenkschere mit zwei austauschbaren Konturschnitt-Messerkassetten

Erfahren Sie mehr über diesen Produktbereich

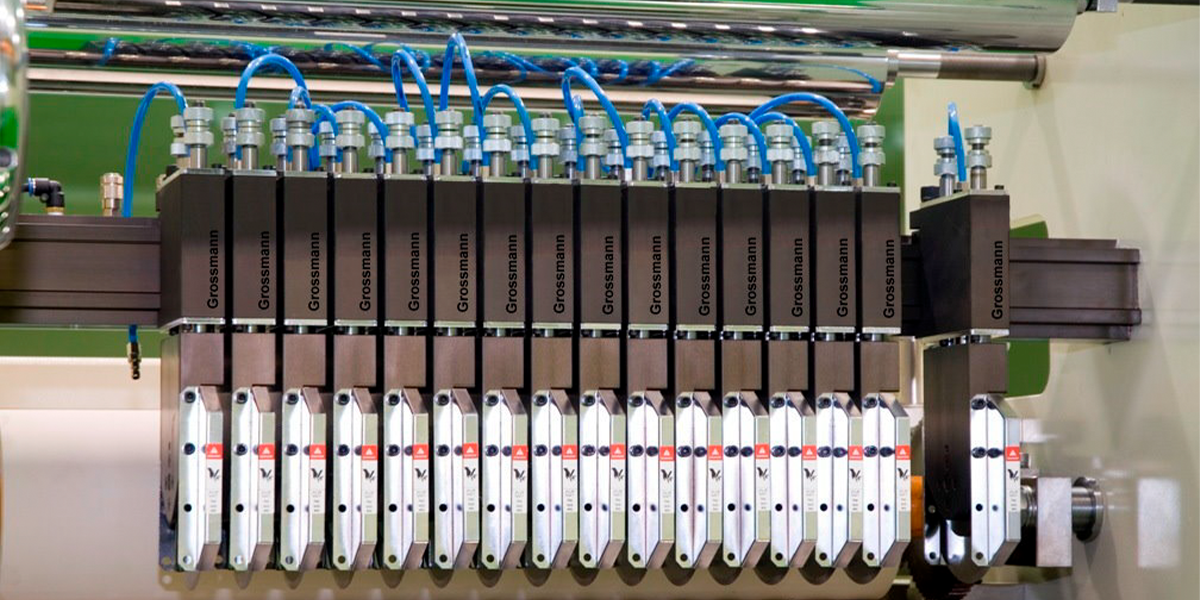

Schneidsysteme

Erfahren Sie mehr über diesen Produktbereich

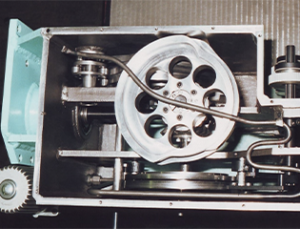

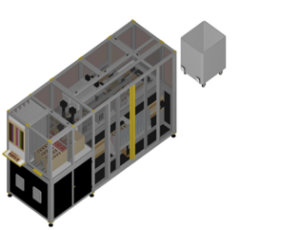

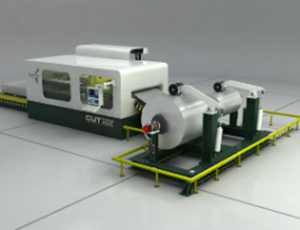

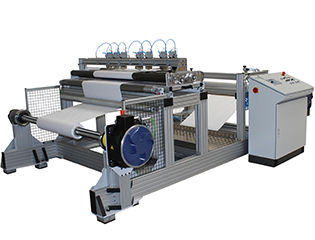

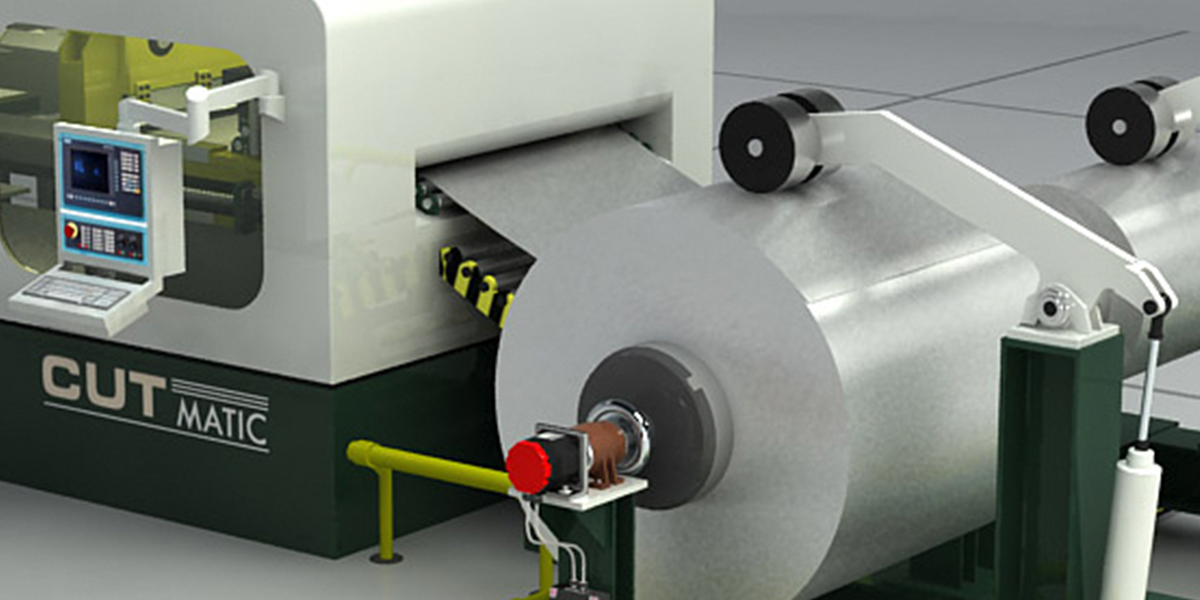

Platinenschneidanlage Cutmatic

Erfahren Sie mehr über diesen Produktbereich

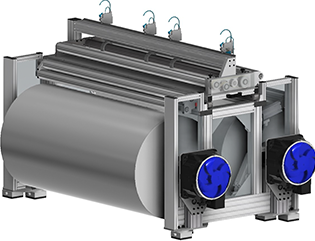

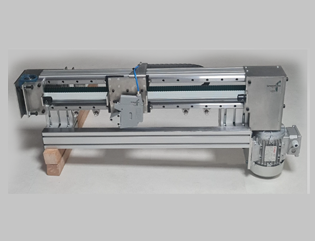

Baugruppen und Maschinen zur Bahnbearbeitung

Erfahren Sie mehr über diesen ProduktbereichDestackers

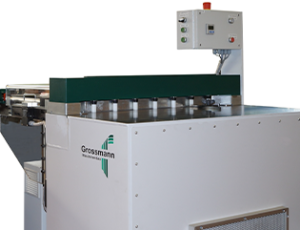

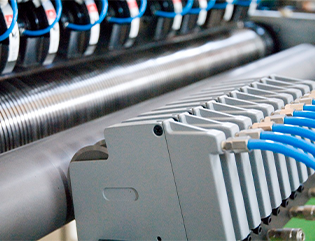

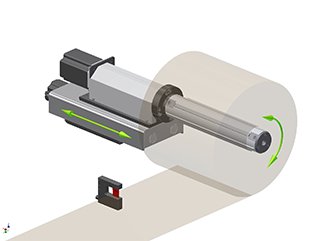

The basic principle of our stackers is the vertical fall of the sheet onto the stack or the vertical removal during destacking. There is no relative movement between the sheet and the stack. This avoids surface damage.

An example is shown in the video clip: The still uncut strip slides on brush plates over the sheet stack. After cutting, the sheet lays across its entire length on the two brush plates. Immediately thereafter, these move apart quickly. Guided laterally, the sheet falls vertically onto the stack. The air cushion forming between the sheet and the stack brakes the fall.

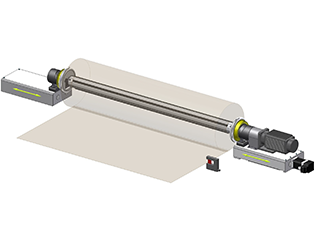

The second part of the video shows intermediate storage on a second pair of brush plates. This allows continuous sheet production even during stack changeover.

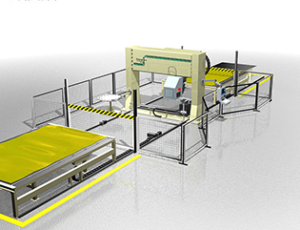

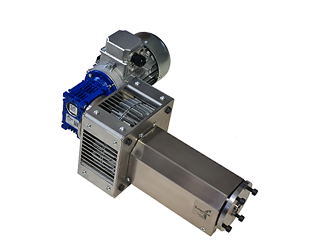

The two photos below show a sheet finishing system for laser-cut sheets. For this, our shear-shock-free, electric servo shear is necessary.

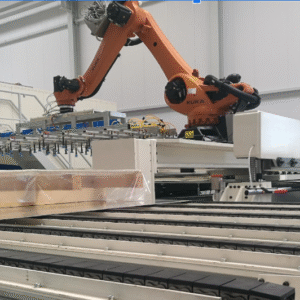

The entire sheet with the cut-out part exits the laser cutting system. The robot removes the cut-out part and stacks it. Destacking occurs alternately to the left of the exit conveyor, then to the right. This enables continuous production even during stack removal.

The waste pieces continue and are disposed of Shredding the waste pieces can be done with a High-Speed Shear.

Grossmann B.V.

Markt 19

NL6071 JD Swalmen

Info@grossmann.de